SERVICES

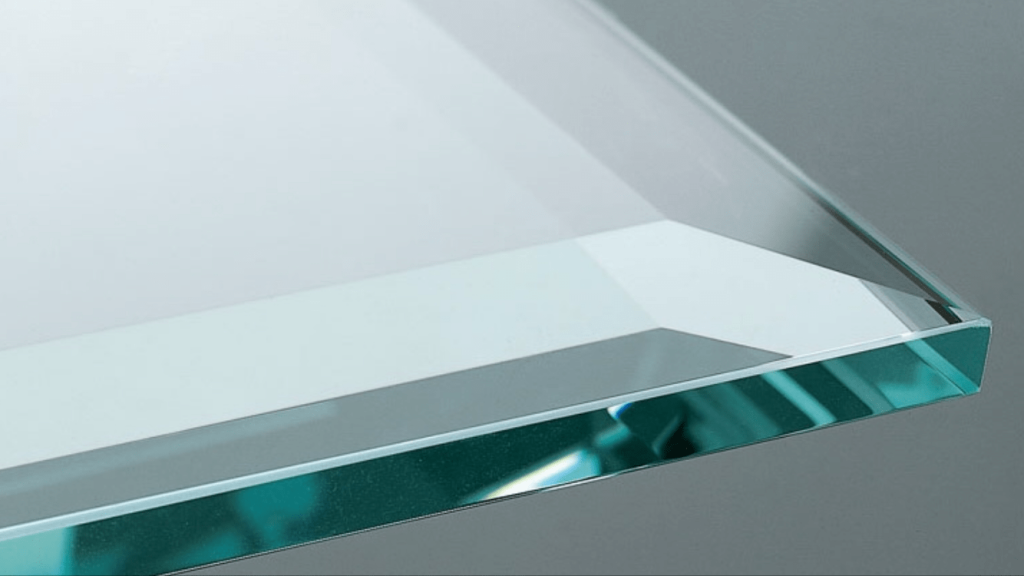

Beveling

Beveling slopes the edge of the glass. This shifts the center to be the thickest portion of the glass while the corners and the edges would be the thinnest. This is accomplished through extensive cutting and polishing of the glass. The usage of this technique is usually when the glass is intended to be the center of attention. The bezel resulted by the bevel can vary and will depend on your specification.

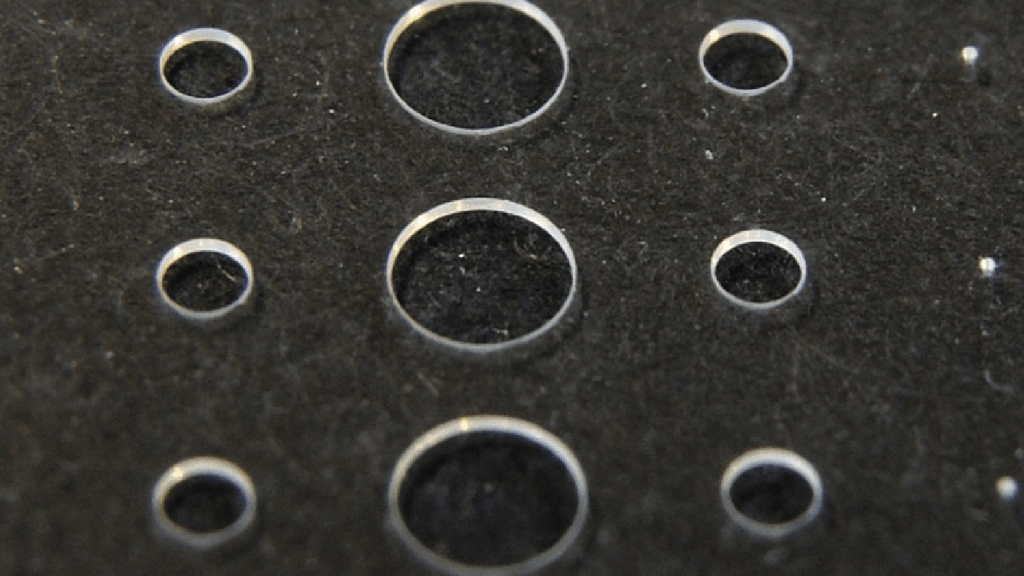

Drilling

We have the tools and the experts required to drill precisely to your exact requirement. Our quality is optimal in cases or large and small orders. Our team has gone through extensive training and has years of experience with the machinery. Hydra guarantees perfect satisfaction of your requirement in terms of precision. We are ready to take on any challenging hole drilling operation and we're confident of our abilities.

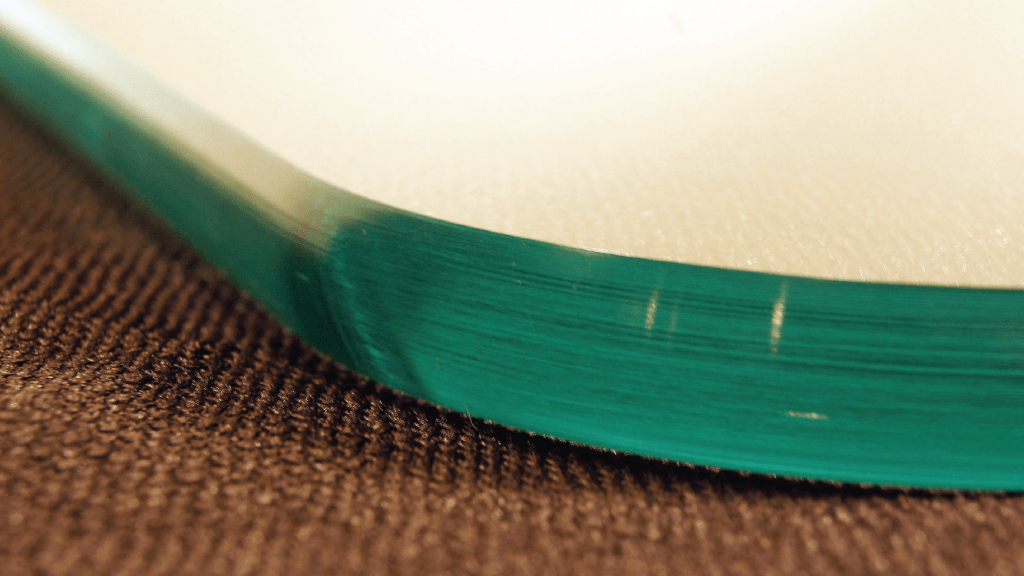

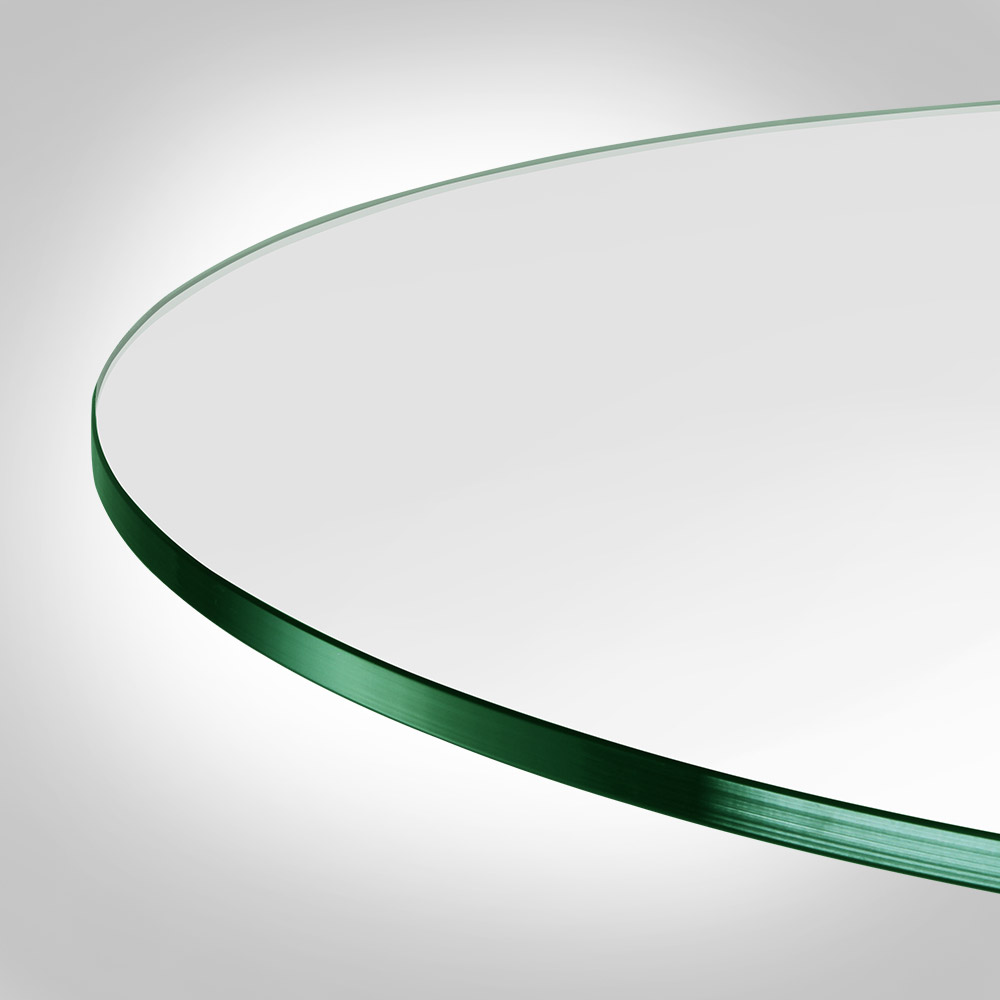

Pencil Edge

Pencil Edges are achieved via rounding the side of the glass. This finish is used in furniture generally due to it being safer than other finishes. Smooth edges prevent potential injuries which maybe important in furniture which is placed in areas where people including children frequent. To achieve this Hydra uses specialized equipment.

Round Edge

Flat Edges result in a sharp and clean look for the Glass. We use sophisticated machinery to remove all the imperfections and to achieve perfect smoothness. Edges could also be chamfered to achieve a more polished look. This finish is used in Mirrors, Displays, Furniture meant for Decoration, Frameless Mirrors and Glass Partitions.

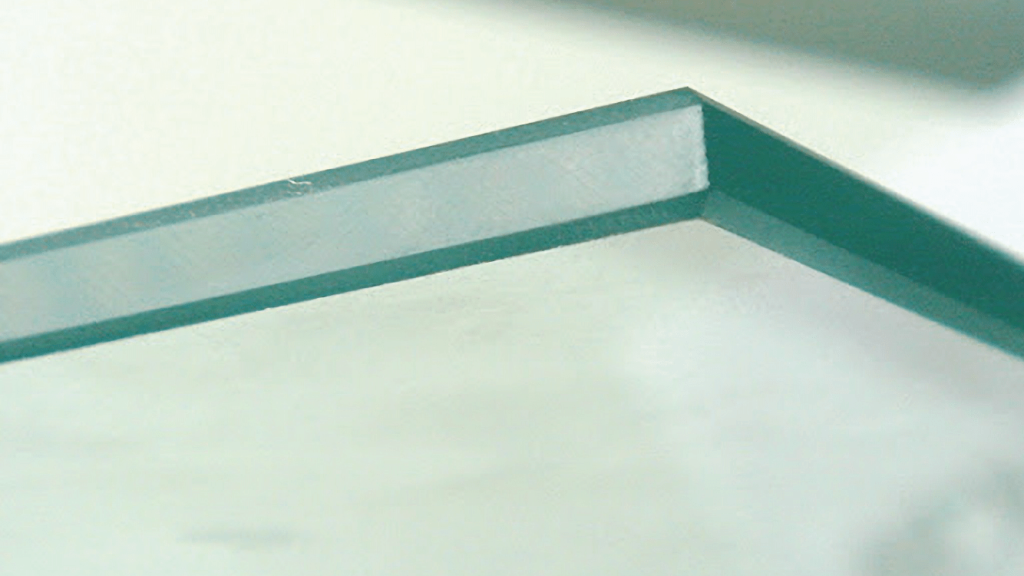

Flat Edge

Flat Edges result in a sharp and clean look for the Glass. We use sophisticated machinery to remove all the imperfections and to achieve perfect smoothness. Edges could also be chamfered to achieve a more polished look. This finish is used in Mirrors, Displays, Furniture meant for Decoration, Frameless Mirrors and Glass Partitions.

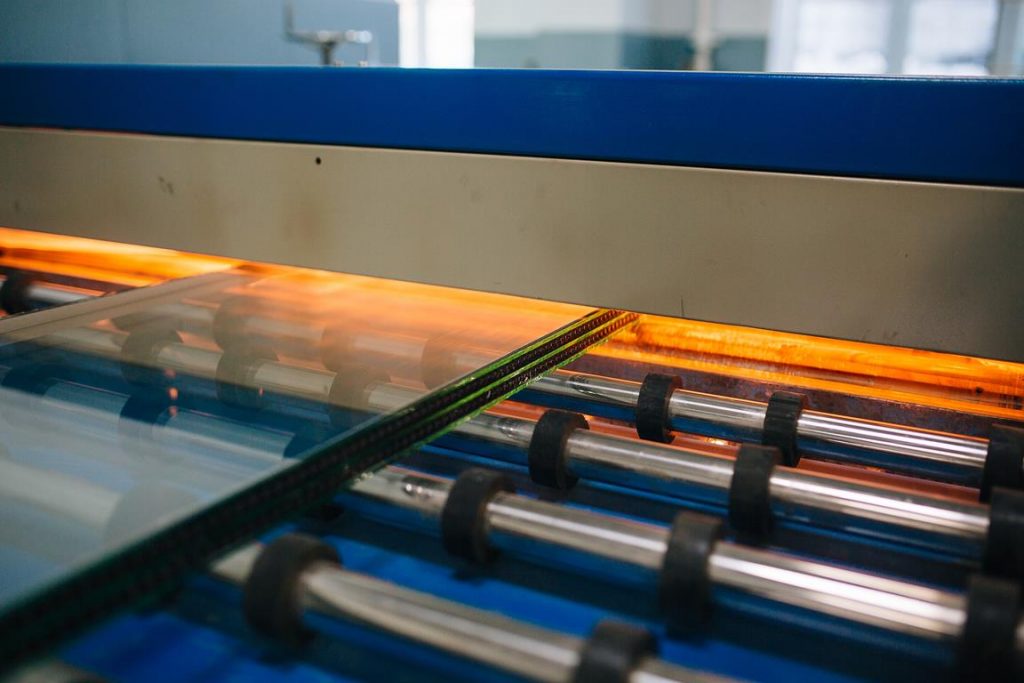

Tempering

Tempering is done to increase the strength of the glass by five times compared to a regular annealed glass. This process starts by cutting the glass to the required size and the glass is inspected in detail to figure out anomalies and if any are found then it's smoothened further to remove those anomalies. Next, the glass is heated to high temperatures in an over and is cooled gradually. The result of this process gives the glass it's strength.

Fabrication

We are capable of performing various types of fabrications such as Lamination, Insulation, Decoration, Bending and Opacifying Glass. Our services uses state-of-art facilities to conduct the required fabrication. We employ experts who focus on precision and consider factors such as the smoothness of the edges to ensure your requirement is satisfied.